Fundamentals of Fluid Flow in Porous Media

Chapter 5

Miscible Displacement

Fluid Properties in Miscible Displacement: Macroscopic Displacement Efficiency

Mobility Ratio[1], [2]

The mobility of a fluid (i) is defined as :

Where,

μi = Viscosity,

Ki = Effective permeability of the rock to fluid i.

The mobility ratio (M) of a displacement process is defined as the mobility of displacing fluid divided by the mobility of the displaced fluid. Mobility ratio is one of the most important parameters of a miscible displacement and has a profound influence on volumetric (macroscopic) sweep efficiency of the solvent and on the integrity of solvent slugs. Consider an idealized situation where solvent displaces oil at the irreducible water saturation (secondary recovery process) and where mixing of solvent with the oil is negligible. No water is flowing and the permeabilities to oil and solvent are equal. Mobility ratio in this case is simply the ratio of oil and solvent viscosities:

In practice mixing of solvent and oil does occur during the course of the displacement, which can result in an effective viscosity ratio that is less than the ratio of pure component viscosities. The viscosities of miscible solvent are typically small (< 0.1 cp) and thus the mobility ratios are greater than one. Viscosity ratio or mobility ratio, as defined by eq. (5‑34), ranges from 4 to 86 in the different MCM processes. Stalkup[2] reports data on a number of FCM projects. For these, the viscosity ratio ranges from 4 to 40. When the mobility ratio is smaller than one it is called favorable mobility ratio and called unfavorable when it is greater than one. Solvent/water injection is a technique to reduce solvent mobility by reducing solvent relative permeability. The most accepted mobility ratio definition at presence of mobile water is:

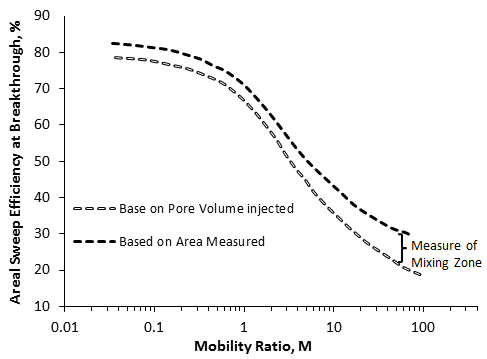

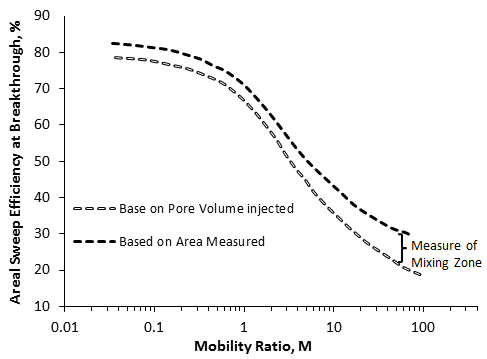

Figure 5‑32 gives areal sweep efficiency (fraction of the pattern area invaded by pure solvent) at breakthrough of the displacing fluid as a function of M. the upper curve is based on photographs taken during displacement of one colored liquid by a second, miscible colored liquid in a scaled model, while the lower one is based on a material balance calculation made from the known volume of injected liquid and assuming piston like displacement. Because of mixing along the liquid-liquid interface, the area measurement yields a slightly larger areal sweep value than material balance result. As indicated in Fig. 4.4, the difference in the two curves is a measure of the mixing that occurs at the interface.

As seen, the areal sweep efficiency (EA) at breakthrough is a strong function of M. at M=1.0, areal sweep is about 70%. It increases slightly at smaller, favorable mobility ratios and decreases very sharply as M is increased. The poorer performance at larger M values occurs for two reasons: first viscous fingering occurs at M > 1.0 and become more noticeable as M increases. Second for M > 1.0 the geometry contribute to the early breakthrough. Because of the geometry, the smallest flow resistance and therefore the larger flow velocity is along the center line connecting the injection and production wells. Fluid flowing along this line breaks through first in a homogeneous reservoir. When M > 1.0 the fluid with lower mobility value (displaced fluid), is replaced by the injected fluid (with higher mobility). Because the major flow is along the center line path (as the shortest pass), the resistance along that path is reduced more than along any other line other than path. The result is that the larger the value of M the earlier breakthrough occurs.

Figure 5-32: Areal Sweep Efficiency as a Function of Mobility Ratio[3]

References

[1] “Enhanced Oil Recovery”, Don, W. Green, G. Paul Willhite, 1998

[2] “Miscible Dispalcement”, Stulkup Jr., F.I., Monograph series, SPE, Richardson, TX(1983).

[3] “Efficiencies of miscible displacement as a function of mobility ratio”, Trans, AIME (1960)219, 264-72

Questions?

If you have any questions at all, please feel free to ask PERM! We are here to help the community.

The mobility of a fluid (i) is defined as :

Where,

μi = Viscosity,

Ki = Effective permeability of the rock to fluid i.

The mobility ratio (M) of a displacement process is defined as the mobility of displacing fluid divided by the mobility of the displaced fluid. Mobility ratio is one of the most important parameters of a miscible displacement and has a profound influence on volumetric (macroscopic) sweep efficiency of the solvent and on the integrity of solvent slugs. Consider an idealized situation where solvent displaces oil at the irreducible water saturation (secondary recovery process) and where mixing of solvent with the oil is negligible. No water is flowing and the permeabilities to oil and solvent are equal. Mobility ratio in this case is simply the ratio of oil and solvent viscosities:

In practice mixing of solvent and oil does occur during the course of the displacement, which can result in an effective viscosity ratio that is less than the ratio of pure component viscosities. The viscosities of miscible solvent are typically small (< 0.1 cp) and thus the mobility ratios are greater than one. Viscosity ratio or mobility ratio, as defined by eq. (5‑34), ranges from 4 to 86 in the different MCM processes. Stalkup[2] reports data on a number of FCM projects. For these, the viscosity ratio ranges from 4 to 40. When the mobility ratio is smaller than one it is called favorable mobility ratio and called unfavorable when it is greater than one. Solvent/water injection is a technique to reduce solvent mobility by reducing solvent relative permeability. The most accepted mobility ratio definition at presence of mobile water is:

Figure 5‑32 gives areal sweep efficiency (fraction of the pattern area invaded by pure solvent) at breakthrough of the displacing fluid as a function of M. the upper curve is based on photographs taken during displacement of one colored liquid by a second, miscible colored liquid in a scaled model, while the lower one is based on a material balance calculation made from the known volume of injected liquid and assuming piston like displacement. Because of mixing along the liquid-liquid interface, the area measurement yields a slightly larger areal sweep value than material balance result. As indicated in Fig. 4.4, the difference in the two curves is a measure of the mixing that occurs at the interface.

As seen, the areal sweep efficiency (EA) at breakthrough is a strong function of M. at M=1.0, areal sweep is about 70%. It increases slightly at smaller, favorable mobility ratios and decreases very sharply as M is increased. The poorer performance at larger M values occurs for two reasons: first viscous fingering occurs at M > 1.0 and become more noticeable as M increases. Second for M > 1.0 the geometry contribute to the early breakthrough. Because of the geometry, the smallest flow resistance and therefore the larger flow velocity is along the center line connecting the injection and production wells. Fluid flowing along this line breaks through first in a homogeneous reservoir. When M > 1.0 the fluid with lower mobility value (displaced fluid), is replaced by the injected fluid (with higher mobility). Because the major flow is along the center line path (as the shortest pass), the resistance along that path is reduced more than along any other line other than path. The result is that the larger the value of M the earlier breakthrough occurs.

Figure 5-32: Areal Sweep Efficiency as a Function of Mobility Ratio[3]

References

[1] “Enhanced Oil Recovery”, Don, W. Green, G. Paul Willhite, 1998

[2] “Miscible Dispalcement”, Stulkup Jr., F.I., Monograph series, SPE, Richardson, TX(1983).

[3] “Efficiencies of miscible displacement as a function of mobility ratio”, Trans, AIME (1960)219, 264-72

Questions?

If you have any questions at all, please feel free to ask PERM! We are here to help the community.