Fundamentals of Fluid Flow in Porous Media

Chapter 5

Miscible Displacement

Introduction

In an immiscible displacement process, such as water flooding, the microscopic displacement efficiency, eq. (5‑1), is generally much less than unity.

Where,

Soi = Initial oil saturation,

Sor = Residual oil saturation after immiscible displacement,

ED = Microscopic displacement efficiency

Part of the crude oil in places contacted by the displacing fluid is trapped as isolated drops, stringers, or pendular rings, depending on the wettability. At this condition relative permeability to oil would be almost zero and no more oil will be produced by continuing displacing fluid injection. In this situation capillary pressure prevent the oil drops to move and pass through constrictions in the pore passages.

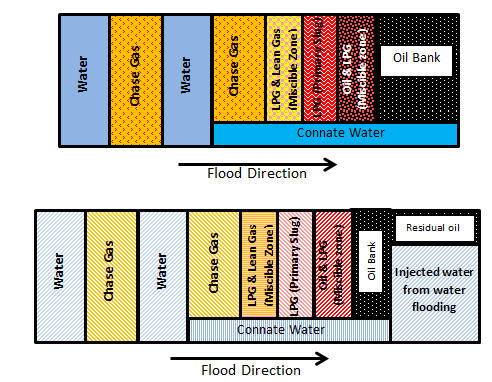

This limitation to oil recovery may be overcome by the application of miscible displacement processes in which the displacing fluid is miscible with the displaced fluid at the condition existing at the interface between the displaced and displacing fluids two fluids that mix together in all proportions within a single fluid phase are miscible. If the two fluids do not mix in all proportions to form a single phase, the process will be immiscible The physics of miscible and immiscible displacement are significantly different. Therefore, different factors dominate these displacements at the pore level, and different phenomena are considered in modeling them. In immiscible displacements in porous media an interface separates the fluids. One fluid is never completely displaced by another, immiscible fluid. There will be irreducible or residual saturations after the displacement has reached steady state. Typical oil residual in displacements by water ( Sorw ) can be 25-40% of the original oil in place (OOIP). In a capillary system, such as a porous medium, the interfacial tensions associated with the immiscible fluid interfaces play a significant role in determining the fluid distributions within the porous medium, as covered under the subject of capillarity. The displacement front in an immiscible displacement will be sharper at higher flow rates, or when capillary forces are neglected. On the other hand, in a miscible displacement, no interface exists between miscible fluids of different composition. In the absence of fluid/fluid interfaces, capillary forces are absent. Steady state is reached when one fluid has completely displaced the other fluid; the concept of irreducible or residual saturations does not apply. This means that by using miscible displacement process we could achieve very high “pore scale” recovery efficiencies. Once the solvent front has moved through a volume of the porous medium containing the original oil, little to no residual oil is left behind. Miscible displacement can be used as a secondary recovery process just after primary recovery of the oil or as a tertiary recovery method at the end of water injection process. The main oil recovery mechanisms during miscible flood are extraction, dissolution, vaporization, solubilization, condensation, or other phase behavior change involving the crude oil, viscosity reduction, oil swelling and solution gas drive, but the primary mechanism must be extraction[2]. In practice, solvents that are miscible with crude oil are more expensive than water or dry gas, so instead of continues solvent injection a slug of the solvent (such as LPG[3] ), with a size of approximately 5% of reservoir pore volume is injected that is followed by a larger volume of a less expensive fluid (chase fluid), such as water or a lean or flue gas (Figure 5‑1). To have an efficient displacement of the primary (solvent) slug, ideally this secondary slug should be miscible with the primary (solvent) slug. To improve the overall sweep efficiency by LPG process, the hydrocarbon slug I displaced by altering the chase gas with water slug and finally with continuous water injection (Figure 5‑1) The miscible displacement process can be classified as first-contact miscible (FCM) or multi-contact miscible (MCM) on the basis of the manner that miscibility developed. In FCM the injected solvent forms only a single phase upon first contact when mixed in all proportion with the crude oil, propane injection is a sample of this process. In the MCM process (dynamic miscibility) miscible conditions are developed in situ through composition alteration of the injected fluid or crude oil (by in situ mass transfer) as the fluid move through the reservoir. These processes are categorized into: The high pressure gas and the enriched gas drive are member of the MCM process. Various gases and liquids are suitable for use as miscible displacement agents in either FCM or MCM processes. These include low-molecular weight hydrocarbons, organic alcohols, ketones, refined hydrocarbons, condensed petroleum gas (LPG), liquefied natural gas (LNG), carbon dioxide, air, nitrogen, exhaust gas, flue gas and mixture of these. It should be mentioned that because there is only one phase in the miscible region, the wettability of the rock and relative permeability lose their importance since there is no interface between fluids. However the mobility ratio, which is defined as the viscosity ratio between miscible solution and the displaced oil, has a significant effect on the recovery efficiency. For a miscible flood to be economically successful in a given reservoir several conditions must be satisfied[4]: [1] “Enhanced Oil Recovery”, D. W. Green and G. P. Willhite, 1998. [2] “Enhanced Oil Recovery”, L. W. Lake, 1989 [4] “Advanced Resevoir Management and Engineering”, T. Ahmed, N. Meehan, 2011. If you have any questions at all, please feel free to ask PERM! We are here to help the community.

Figure 5-1: Miscible Displacement, a) Secondary Recovery, b) Tertiary Recovery

References

Questions?