Fundamentals of Fluid Flow in Porous Media

Chapter 5

Miscible Displacement

Determination of Miscibility Condition: Contact Experiment

Slim tube and RBA methods were introduced as two direct methods for MMP and MME measurements. There are other experimental tests such as contact experiments, that do not measure directly MMP or MME but their results are used to evaluate and calibrate of phase behavior models that can predict these values indirectly; for example when used with 1D compositional simulators to model slim tube displacements, to estimates MMP and MME. In contact experiments the solvent injection processes are simulated in batch type tests in PVT cells. Some of the most useful bath type solvent injection experiments are discussed in the following sections:

Single Contact: a known value of solvent is charged into a visual, high pressure cell containing a known amount of oil. After applying a specific temperature and pressure and equilibrium establishment, a small amount of each phase is withdrawn. The compositions represent the ends of an equilibrium tie line. Single contact experiments are useful for measuring p-x diagrams, since the pressure can be changed at fixed overall composition by changing the cell volume. If the experiment is repeated for various amounts of solvent the single contact experiment traces a dilution path on a ternary diagram between the solvent and oil. The single contact experiment does not simulate the continuous contact between the solvent and oil during a solvent-oil displacement. The static equilibrium tests which closely simulate continuous contact of solvent and reservoir oil are multiple contact experiments.

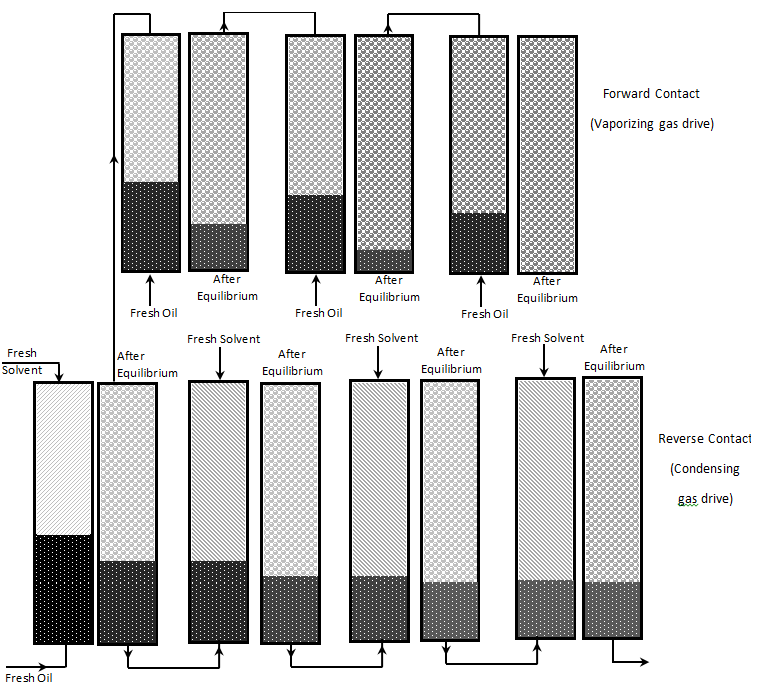

Multiple Contacts: the visual high pressure cell is filled with a known amount of solvent and crude oil, the same as in a single contact test. After reaching equilibrium at the applied pressure the upper phase is removed from the cell and mixed in a second cell with fresh oil, forward contact (the same as the process in downstream contact of a solvent-oil mixing zone in multi contact miscibility process, or the vaporizing gas drive process). The lower phase in the cell is similarly mixed with fresh solvent, reverse contact (the same as what happen in the upstream contact of solvent-oil mixing zone in a multi contact miscibility displacement, or condensing gas drive). The upper phase is repeatedly removed from the cell and adjacent to the fresh oil in another cell. All contacts are at fixed temperature and pressure.

After several steps solvent enrichment in the forward contacts or the rude enrichment in reverse contacts can cause one of the phases to vanish. If the original cell is single phase for all combinations of solvent and crude oil, the process is first contact miscible.

Figure 5-31: Schematic of Multiple Contact Experiment

Questions?

If you have any questions at all, please feel free to ask PERM! We are here to help the community.